Disclosure: This Post Contains Affiliate Links; We earn a commission on purchases.

Electromagnetic interference (EMI) can cause disruptions and even damage to electronic devices. To protect these devices from EMI, various materials are used for electromagnetic field (EMF) shielding. In this article, we will explore the properties and applications of different metals used in EMF shielding. By understanding the properties of these metals, you can make an informed choice for your EMF protection needs.

Key Takeaways:

- Metals play a crucial role in EMF shielding to protect electronic devices from electromagnetic interference.

- The effectiveness of metals in blocking EMF depends on their conductivity, corrosion resistance, and other factors.

- Copper, stainless steel, aluminum, and nickel are commonly used metals for EMF shielding.

- Metal alloys, such as beryllium copper and mu-metal, offer enhanced protection against EMF.

- Choosing the right metal for EMF shielding depends on specific application requirements and budget constraints.

The Importance of EMI Shielding

EMI shielding materials play a crucial role in protecting sensitive electronic devices from electromagnetic interference. When electronic devices emit energy, such as magnetic or electrical waves, EMI shielding materials prevent these waves from interfering with the device’s internal workings. This is particularly important in critical applications like medical devices or aviation equipment, where even minor interference can lead to catastrophic failures. By using EMI shielding materials, static, background noise, and other external interferences can be effectively blocked, ensuring the proper functioning of the device.

Considerations and Impact of Material Used

When selecting an EMI shielding product, several factors should be considered. These include the type of interferences to be blocked, the operating environment of the device, and the budget allocated for the project. Choosing the right material is crucial as it directly impacts the shielding effectiveness, galvanic compatibility, conductivity, anti-corrosion properties, weight, durability, design, performance, and cost of the EMI shielding product.

Firstly, the shielding effectiveness of the material is vital in providing adequate protection against electromagnetic interferences. The material should have high conductivity to efficiently block and redirect electromagnetic waves, ensuring minimal leakage and maximum shielding.

Secondly, galvanic compatibility is essential to consider, especially in applications where different metals come into contact. Incompatibility between metals can lead to corrosion, compromising the overall effectiveness of the EMI shielding product. Therefore, choosing materials with compatible galvanic properties is crucial for long-term performance.

Another critical factor to evaluate is the conductivity of the material. High conductivity enables effective absorption and dissipation of electromagnetic waves, reducing the risk of interference. Conductivity also plays a role in minimizing signal loss, maintaining optimal performance of the shielded electronic device.

Furthermore, anti-corrosion properties are important for ensuring the durability and longevity of the EMI shielding product. Corrosion-resistant materials safeguard against degradation caused by exposure to harsh environmental conditions, extending the lifespan of the shielding material and preserving its performance over time.

Weight and durability are also considerations during material selection. The weight of the material can impact the overall weight of the device or equipment, affecting portability or other design aspects. Additionally, durability is crucial for applications in demanding environments where the shielding material must withstand physical stress, temperature variations, and other challenging conditions.

Design flexibility is another factor to take into account. Different materials offer varying options for customization and integration into specific designs. It is essential to choose a material that aligns with the design requirements of the device or equipment, ensuring seamless integration and optimal performance.

Finally, cost is an important consideration, as it directly impacts the feasibility and affordability of the EMI shielding solution. Balancing the desired performance and quality with cost-effectiveness is crucial to ensure the project remains within budget while meeting the necessary shielding requirements.

By carefully considering these factors during material selection, one can make an informed decision regarding the EMI shielding product, maximizing effectiveness, durability, and cost-efficiency. Achieving the right balance between various considerations is key to implementing a reliable and robust EMI shielding solution.

Metals Used in EMI Shielding

Several metals are commonly used for EMI shielding due to their unique properties. The following metals offer different advantages and are widely utilized in various applications:

Copper

Copper is a versatile metal that blocks both radio and magnetic waves. It is often combined with other metals to enhance resistance to corrosion.

Beryllium Copper

Beryllium copper is a copper alloy with enhanced shielding properties and mechanical spring properties, making it ideal for certain applications.

Copper Alloy

Copper alloys, such as Alloy 770, offer significant corrosion resistance and high tensile strength, making them durable and reliable for EMI shielding.

Stainless Steel

Stainless steel is a stiffer material that is highly corrosion-resistant. It is suitable for specific applications where sturdiness is required.

Aluminum

Aluminum has a high strength-to-weight ratio, making it durable and cost-effective. Its lightweight nature makes it an excellent choice for various shielding purposes.

Pre-Tinplated Steel

Pre-tinplated steel provides cost-effective shielding against lower-frequency EMI, making it an economical choice for shielding applications.

Nickel

Nickel is a versatile and cost-effective metal that can be used as plating or combined with other metals to increase conductivity in EMI shielding applications.

Monel

Monel is a strong alloy with excellent corrosion resistance and good conductivity, making it suitable for several EMI shielding requirements.

Mu-metal

Mu-metal, made of nickel and iron, effectively shields both electronic and magnetic fields, providing reliable protection for sensitive electronic devices.

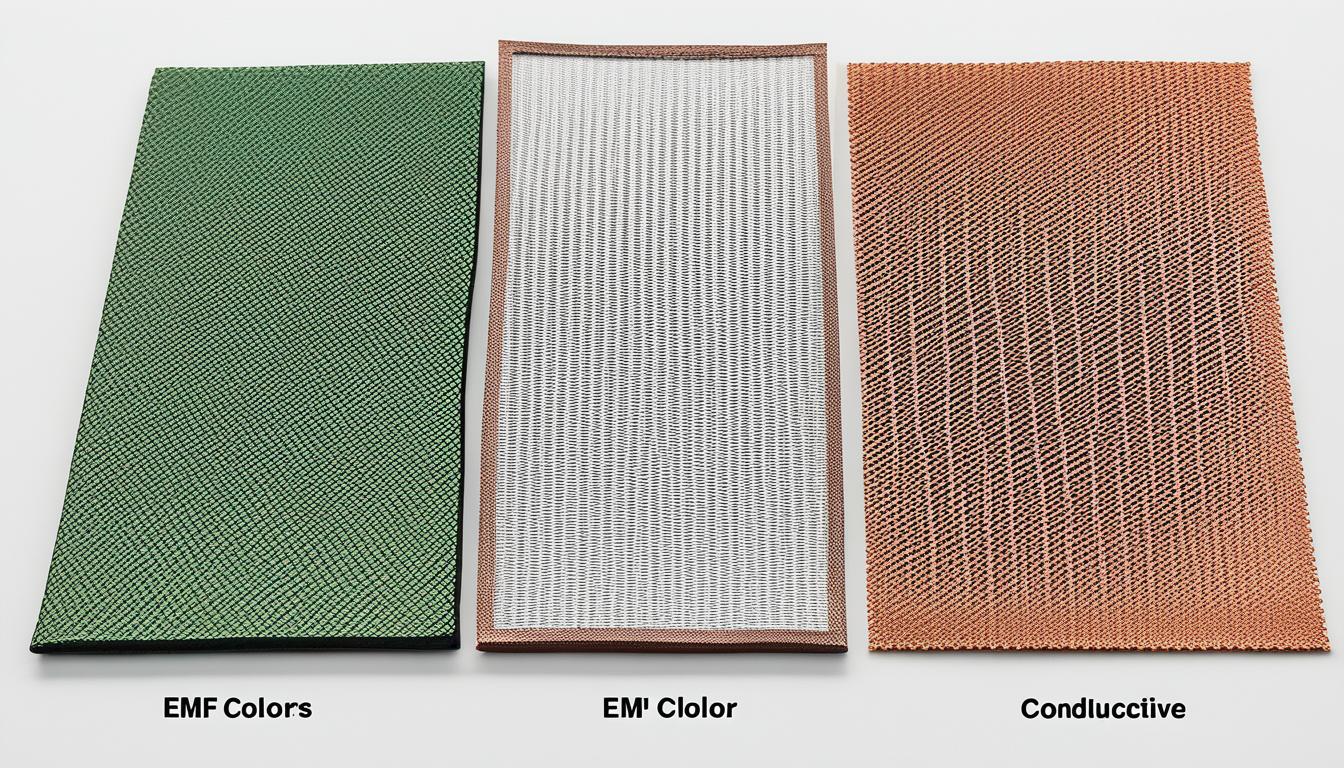

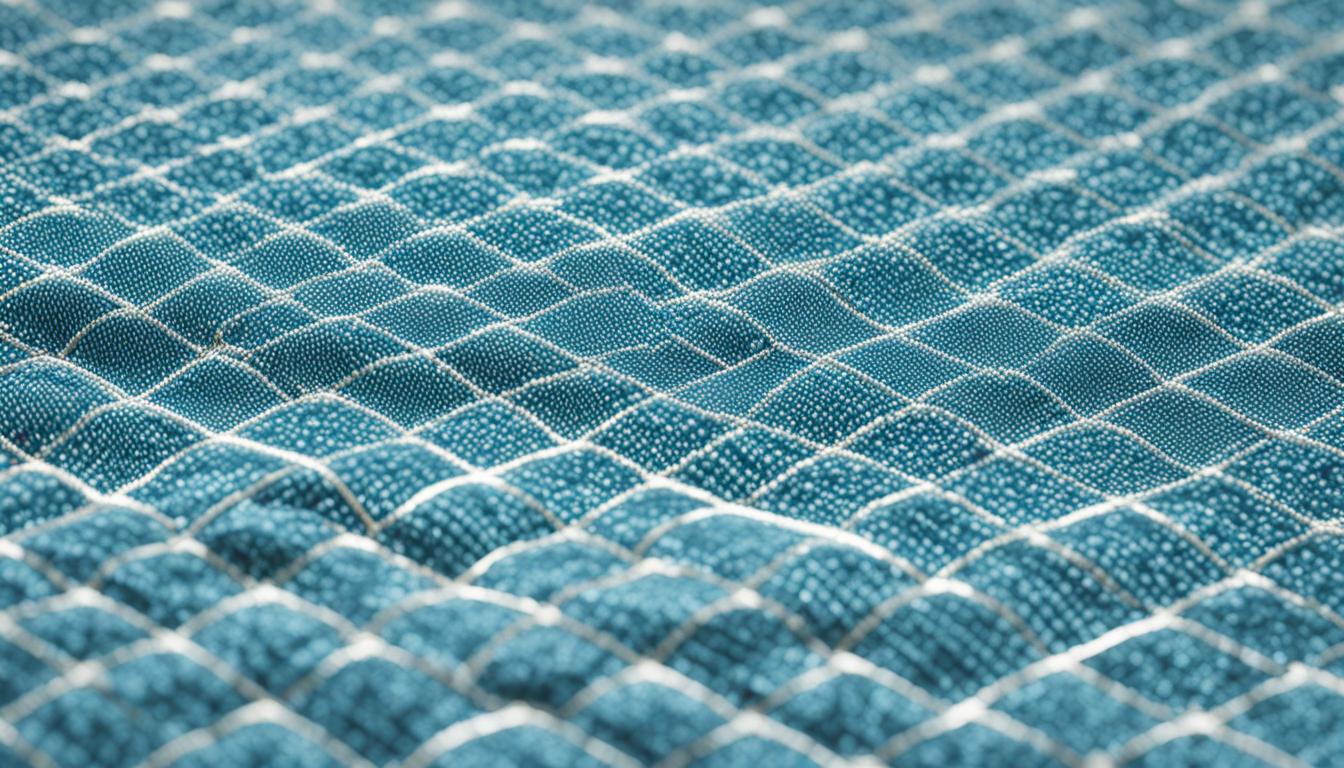

Metal Combinations

In addition to these individual metals, metal combinations such as mesh composite gaskets, metalized fabric gaskets, conductive foam gaskets, and conductive elastomers provide flexible and lightweight EMI shielding solutions.

By utilizing these metals and metal combinations, industries can achieve effective electromagnetic interference shielding, safeguarding electronic devices from potential disruptions and maintaining reliable operation.

What Is the Best Choice for EMI Shielding?

Selecting the right EMI shielding material is a critical decision that depends on various factors. It is essential to consider the frequencies that need to be blocked, the specific requirements of the project, and the application functions of the device. By carefully evaluating these aspects, you can determine the best metal for EMI shielding.

- Copper: With its versatility and high conductivity, copper is a popular choice for EMI shielding. It effectively blocks electromagnetic fields and offers excellent performance across a wide range of frequencies.

- Brass: Brass is an affordable option that provides good electrical and corrosion resistance. It also has high-temperature tolerance, making it suitable for demanding applications.

- Aluminum: Lightweight and durable, aluminum is a cost-effective choice for EMI shielding. It offers good conductivity and is commonly used in various industries.

- Gold: Gold is an effective option for high-frequency applications. It provides excellent corrosion resistance and ensures reliable performance in demanding environments.

- Nickel and Nickel Alloys: Known for their durability and corrosion resistance, nickel and nickel alloys are suitable for low-frequency applications. They offer reliable EMI shielding while maintaining structural integrity.

When making the decision, it’s crucial to carefully consider the unique needs of your project and consult with experts in the field. Their expertise can help you identify the EMI shielding material that best suits your specific requirements, ensuring optimal performance and protection for your electronic devices.

Radio Frequency Shielding Materials

When it comes to blocking electromagnetic interference (EMI) in sensitive applications, radio frequency (RF) shielding materials play a crucial role. The effectiveness of an RF shield depends on various factors, including the thickness and composition of the material used.

The most commonly effective materials for RF shielding are copper and bronze. These metals are known for their excellent conductivity and shielding properties. Additionally, aluminum, gold, and brass are also used for RF shielding due to their conductive properties and effectiveness in repelling frequencies. The choice of material depends on factors such as the type of electronics being protected and the specific frequencies that need to be blocked.

The thickness of the shielding material is another critical factor in its effectiveness. Thicker materials provide better shielding capabilities by blocking a greater amount of electromagnetic waves. The application method of the shielding material also plays a role in its effectiveness. Whether it is applied as a coating, a tape, or integrated into the device’s design, the method should be chosen carefully to ensure optimal shielding performance.

Aside from its functional benefits, the choice of RF shielding material can also have cosmetic reasons. Some materials may offer a more aesthetically pleasing appearance, especially when used in consumer electronics or other visible applications. Careful consideration should be given to both the technical and cosmetic aspects when selecting RF shielding materials for a specific application.

Choosing the Right Material for RF Shielding

When it comes to RF shielding, selecting the right material is crucial. Several factors should be considered, including conductivity, durability, corrosion resistance, and compatibility with other materials. Let’s explore some of the key materials used in RF shielding and their unique properties:

Copper

Copper is renowned for its excellent conductivity, making it one of the top choices for RF shielding. Its high conductivity allows for efficient electromagnetic field blocking. Copper is commonly used in applications like MRI machines, where reliable shielding is essential.

Brass

Brass offers an affordable and versatile option for RF shielding. It combines electrical resistance, corrosion resistance, and high-temperature tolerance. These properties make brass suitable for various shielding applications.

Aluminum

Aluminum is a lightweight and cost-effective material that provides good conductivity for RF shielding. Its durability and easy availability make it a popular choice for shielding applications.

Gold

Gold is highly effective for RF shielding in high-frequency applications. It offers excellent corrosion resistance and is often used in sensitive electronic devices where signal integrity is critical.

Nickel and Nickel Alloys

Nickel and nickel alloys are known for their durability and resistance to corrosion. These materials are commonly used in RF shielding to ensure long-term protection against electromagnetic interference.

Considerations for Other Materials

While copper, brass, aluminum, gold, and nickel alloys are popular choices for RF shielding, materials like steel, zinc, and magnesium may not be suitable. These materials can present durability issues and potential unwanted reactions when in contact with other metals, compromising the effectiveness of the shielding.

When selecting a material for RF shielding, carefully consider the specific requirements of your application. Conductivity, durability, corrosion resistance, and compatibility should guide your choice of material. By choosing the right material, you can ensure effective RF shielding and dependable performance for your electronic devices.

| Material | Conductivity | Durability | Corrosion Resistance |

|---|---|---|---|

| Copper | High | Good | Excellent |

| Brass | High | Good | Excellent |

| Aluminum | Good | Excellent | Good |

| Gold | High | Good | Excellent |

| Nickel and Nickel Alloys | Good | Excellent | Good |

| Steel | Low | Excellent | Good |

| Zinc | Low | Good | Excellent |

| Magnesium | Low | Good | Good |

Note: The table above provides a comparison of different materials commonly used in RF shielding based on their conductivity, durability, and corrosion resistance.

Conclusion

In conclusion, when it comes to protecting sensitive electronic devices from electromagnetic interference (EMI), choosing the right material for EMF shielding is of utmost importance. There are various metals that are commonly used for EMI shielding, including copper, beryllium copper, copper alloys, stainless steel, aluminum, pre-tinplated steel, nickel, monel, and mu-metal. Each of these metals offers unique properties such as conductivity, corrosion resistance, and durability, making them suitable for different applications.

In addition to individual metals, metal combinations and composite materials provide flexible and lightweight solutions for EMI shielding. These materials can be tailored to meet specific requirements and offer enhanced shielding effectiveness. By carefully considering the specific needs of your application, such as the frequencies to be blocked and the operating environment, you can choose the best material for your EMI shielding needs.

Whether you’re looking to shield medical devices, aviation equipment, or other sensitive electronic devices, selecting the right material is essential. By utilizing metals and materials specifically designed for EMI shielding, you can ensure the reliable operation of your electronic devices and protect them from disruptive electromagnetic interference. Make an informed decision and choose the right material for effective EMF shielding.

Source Links

- https://www.idgroup.ca/blog/emi-shielding-metals-materials/

- https://www.e-fab.com/what-materials-are-best-for-rf-shields/

- https://leadertechinc.com/the-three-most-popular-shielding-metals-and-what-you-should-know-about-them/

Subscribe to Our Newsletter