Disclosure: This Post Contains Affiliate Links; We earn a commission on purchases.

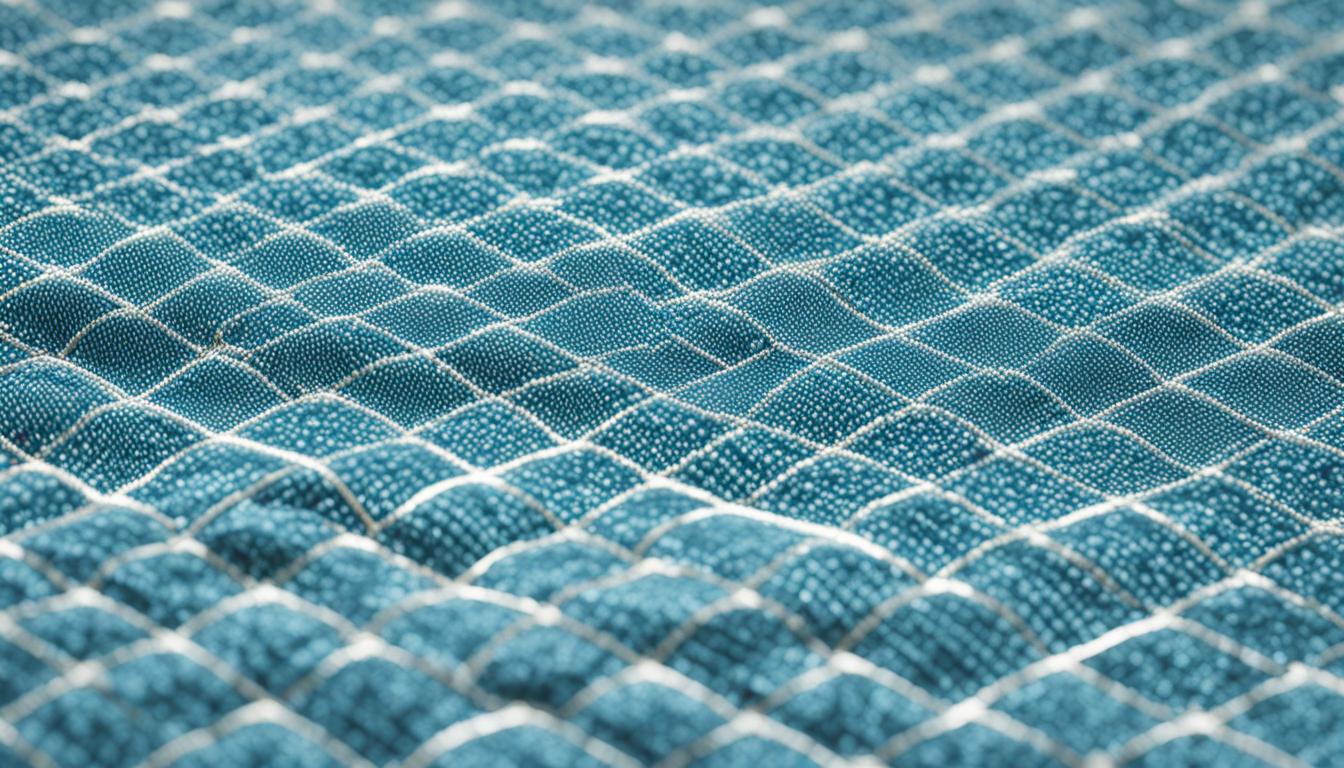

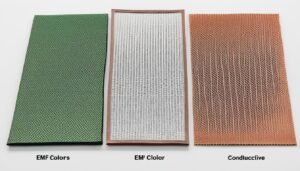

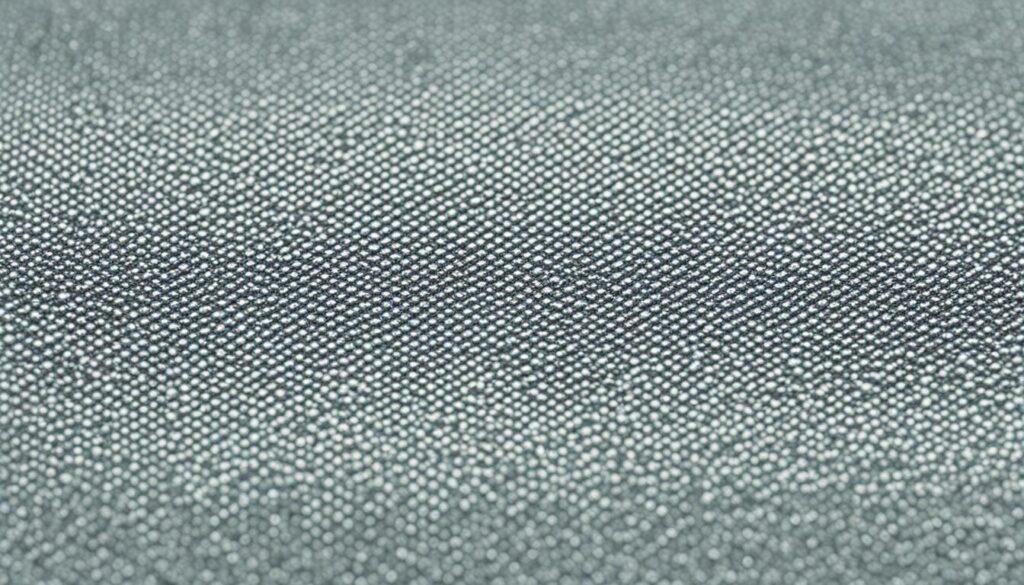

Conductive fabrics are revolutionizing the field of electromagnetic field (EMF) shielding, providing essential protection against the harmful effects of EMFs. These specialized textiles are engineered to absorb or reflect electromagnetic radiation, offering reliable defense against EMF exposure. With their lightweight, flexible, and versatile nature, conductive fabrics have gained significant attention in recent years.

Researchers have been exploring various materials and techniques to enhance the shielding properties of conductive fabrics. From copper aluminum ferrite to reduced graphene oxide, carbon nanotubes to polypyrrole, the impact of different materials on conductivity and shielding effectiveness has been extensively studied. Additionally, studies have investigated the physical properties of these fabrics, such as electrical conductivity, thickness, and composition, which significantly influence their EMF shielding capabilities.

Advanced techniques, like two-dimensional MXenes, have also shown promise as coatings for enhancing the conductivity and shielding effectiveness of fabric composites. MXenes, derived from three-dimensional MAX phases, offer increased stability and conductivity while maintaining the flexibility and drapeability of textile fabrics.

Key Takeaways:

- Conductive fabrics are specifically designed to shield against EMFs and absorb or reflect electromagnetic radiation.

- Their lightweight and flexible nature make them highly versatile for various applications.

- Different materials, such as copper aluminum ferrite and carbon nanotubes, influence the conductivity and shielding effectiveness of conductive fabrics.

- Advanced techniques like MXenes show potential for enhancing fabric composites’ conductivity and shielding properties.

- Understanding the properties and applications of conductive fabrics is crucial for effective EMF protection.

The Importance of EMI Shielding Materials

EMI shielding materials play a critical role in protecting humans, instruments, and electronic equipment from the detrimental effects of electromagnetic interference (EMI). These materials are specifically designed to absorb or reflect electromagnetic radiation, or a combination of both, thereby offering effective shielding against EMI.

The ability of a material to block EM radiation is measured through shielding effectiveness. Reflection, absorption, and multiple reflections within the material influence this effectiveness. Various factors such as electrical and magnetic conductivity, thickness, and composition determine the shielding properties of the material.

Reflective losses are advantageous for shielding materials, while effective absorption losses require the presence of electric or magnetic dipoles. To assess the shielding effectiveness of different materials, methods like coaxial transmission-line methods, shielded-box methods, shielded-room methods, and open-field methods are employed.

Understanding the properties of EMI shielding materials, such as their reflection, absorption, and multiple reflections, is crucial for effective protection against EM radiation.

“EMI shielding materials are instrumental in safeguarding against electromagnetic interference, taking into account factors like reflection, absorption, and multiple reflections within the material.”

Table: Comparing Shielding Effectiveness of EMI Shielding Materials

| Material | Shielding Effectiveness |

|---|---|

| Copper | 85 dB |

| Aluminum | 80 dB |

| Nickel | 70 dB |

Key Factors Influencing Shielding Effectiveness

- Electrical and magnetic conductivity

- Material thickness

- Composition

- Frequency range

- Surface quality

By considering these factors and utilizing high-quality EMI shielding materials, the protection against electromagnetic interference can be significantly enhanced.

MXene: A Promising Material for EMI Shielding Textiles

MXene, a class of two-dimensional materials, holds great promise for enhancing the conductivity and shielding effectiveness of textile fabrics. MXenes are derived from three-dimensional MAX phases by etching the sp element layers, resulting in two-dimensional layers of early transition metal carbides, nitrides, and carbonitrides. These materials possess additional functional groups, such as -OH, -O, and -F, which contribute to their chemical properties.

One of the significant advantages of MXenes is their high conductivity, making them an ideal choice for improving the performance of EMI shielding fabrics. MXene coatings can be applied to textile fabrics either alone or in combination with conductive polymers, metals, or carbon-based fillers. This combination enhances the EMI shielding properties of the fabrics, ensuring better protection against electromagnetic radiation.

However, one challenge that researchers still face is the susceptibility of MXenes to oxidation in humid environments. Addressing this challenge is essential to improve the stability of MXene coatings on textiles, making them more reliable and durable for long-term use.

Despite this challenge, MXenes show great potential for developing high-performance EMI shielding materials. Their unique properties, including their two-dimensional nature, conductivity, and compatibility with textiles, make them an exciting area of research in the field of EMI shielding fabrics.

Enhancing EMI Shielding with Conductive Textile Fabrics

Conductive textile fabrics offer a unique opportunity to enhance the effectiveness of electromagnetic interference (EMI) shielding. These fabrics, known for their inherent flexibility, drapability, and lightweight nature, can be combined with conductive coatings or fibers to achieve optimal EMI shielding performance [2].

EMI shielding in conductive textile fabrics is achieved through a combination of reflection and absorption losses [11]. Several factors, such as fabric thickness, porosity, and the amount of conductive and magnetic materials, play a significant role in determining the overall shielding effectiveness of these fabrics [11,14].

To assess the conductive properties of textile fabrics, various measurement methods can be employed. Techniques like four-probe measurements are commonly used to evaluate the electrical conductivity of conductive textile fabrics [15-17]. While extensive research has been conducted on electrical conductivity, studies on the magnetic properties of these fabrics are relatively limited [21-25].

Measurement methods play a crucial role in assessing the shielding effectiveness of different materials. Open-field, shielded-box, shielded-room, and coaxial transmission-line methods are commonly used to evaluate the effectiveness of conductive textile fabrics in shielding against EMI [26].

By understanding the properties of conductive textile fabrics and employing appropriate measurement techniques, researchers can develop advanced materials that offer enhanced EMI shielding capabilities and meet the requirements of various applications.

Key Factors Influencing the Shielding Effectiveness of Conductive Textile Fabrics:

- Fabric Thickness

- Porosity

- Amount of Conductive Materials

- Amount of Magnetic Materials

Measurement Methods for Shielding Effectiveness of Conductive Textile Fabrics:

- Open-Field Method

- Shielded-Box Method

- Shielded-Room Method

- Coaxial Transmission-Line Method

By continually exploring the properties and measurement techniques of conductive textile fabrics, researchers can develop advanced solutions that enhance EMI shielding and pave the way for a wide range of applications.

| Factors Influencing Shielding Effectiveness | Measurement Methods |

|---|---|

| Fabric Thickness | Open-Field Method |

| Porosity | Shielded-Box Method |

| Amount of Conductive Materials | Shielded-Room Method |

| Amount of Magnetic Materials | Coaxial Transmission-Line Method |

Advancements in EMI Shielding Textile Applications

The advancements in EMI shielding textile applications have revolutionized the potential of smart textiles, extending their capabilities beyond EMF protection. One notable achievement is the development of textile fabrics coated with MXenes, a class of two-dimensional materials. These fabrics exhibit enhanced EMI shielding properties, as well as additional functionalities that include photothermal conversion and solar water evaporation.

The use of MXene coatings, in combination with SiO2 nanoparticles and poly(dimethylsiloxane), has also resulted in the creation of superhydrophobic textiles. These fabrics demonstrate improved EMI shielding effectiveness, providing an added layer of protection against electromagnetic radiation.

Furthermore, conductive textile fabrics have been explored for applications in joule heating and piezoresistive sensing. The integration of conductive materials, including MXenes, into textile-based sensors opens up possibilities for the development of wearable technologies and flexible electronics.

The key advantage of conductive textile fabrics lies in their unique properties of flexibility and lightweight nature. These qualities make them suitable for a wide range of innovative applications. For instance, textiles with electromagnetic wave scattering properties have the potential to manipulate and control EM waves, enabling advanced communication systems and signal processing.

As the field of EMI shielding textile applications continues to evolve, researchers are exploring new ways to harness the potential of these fabrics. From smart textiles with integrated functions to the development of textile-based sensors, the advancements in this field promise a future where EMF protection blends seamlessly with innovative technologies.

Conclusion

Conductive fabrics have emerged as a promising solution for EMF shielding in various applications. By combining conductive coatings or fibers with textile fabrics, materials with enhanced EMI shielding properties can be created. The use of MXene coatings on textile fabrics has shown great potential for improving conductivity and shielding effectiveness.

These advancements in EMI shielding textiles have opened up opportunities for the development of smart textiles with integrated functions like photothermal conversion, solar water evaporation, and wearable technologies. The unique properties of conductive fabrics, such as their flexibility, lightweight nature, and ability to be integrated into various textile applications, make them highly desirable for EMF protection and beyond.

Continued research and development in this field will contribute to the advancement of EMF shielding materials and the future of conductive textiles. Conductive fabrics offer a promising solution for EMF shielding and have the potential to revolutionize various industries, including healthcare, aerospace, and electronics. As technological advancements continue, the applications and benefits of conductive fabrics for EMF protection will only continue to expand.

Source Links

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8838001/

- https://www.mdpi.com/2079-6439/11/3/29

- https://lessemf.com/product-category/emf-shielding/fabrics-textiles/

Subscribe to Our Newsletter