Disclosure: This Post Contains Affiliate Links; We earn a commission on purchases.

Creating a safe and protected environment from electromagnetic fields (EMF) requires the use of suitable building materials for EMF shielding. These materials are designed to reduce exposure to EMF and provide effective protection against the potential health risks associated with EMF exposure. Understanding the available options and considerations when choosing these materials is essential for achieving optimal EMF protection.

EMF resistant materials, also known as EMF blocking materials or RF shielding materials, are specifically designed to block or reduce the penetration of electromagnetic fields. They can be used for various applications, including shielding homes, offices, medical facilities, and electronic devices. EMF shielding solutions can range from simple conductive fabrics and paints to advanced shielding materials that provide high attenuation of EMF.

Conductive fabrics, such as silver or copper-based fabrics, are commonly used for EMF protection. These fabrics are made with conductive materials that help to block or redirect EMF, creating a barrier between the source of EMF and the surrounding environment. They can be used to make clothing, bed canopies, curtains, and other items that provide personal EMF protection.

EMF shielding paints are another option for building materials for EMF shielding. These paints contain special additives or metallic particles that help to reflect or absorb EMF. They can be applied to walls, ceilings, and other surfaces to create a shielded environment. EMF shielding paints are often used in conjunction with other shielding materials to provide comprehensive EMF protection.

When selecting building materials for EMF shielding, it is important to consider the specific needs and requirements of the space or device being shielded. Factors such as the frequency of the EMF, the intensity of the EMF source, and the level of shielding effectiveness required should all be taken into account. Consulting with EMF experts or professionals in the field can provide valuable guidance in choosing the most suitable materials.

Key Takeaways:

- Building materials for EMF shielding are essential for creating a safe and protected environment from electromagnetic fields.

- EMF resistant materials, conductive fabrics, and EMF shielding paints are among the options available for EMF protection.

- Considerations such as frequency, intensity, and level of shielding effectiveness are important when selecting building materials for EMF shielding.

- Consulting with EMF experts can provide guidance in choosing the most suitable materials for specific needs.

- Choose building materials that block or reduce the penetration of electromagnetic fields for optimal EMF protection.

Understanding Radiation Shielding and Its Importance

Radiation shielding plays a crucial role in reducing exposure to ionizing radiation and protecting individuals from its harmful effects. The effectiveness of shielding is based on the principle of attenuation, which refers to the ability of a barrier material to block or bounce the effects of radio waves or rays. This section explores the importance of radiation shielding and the different types of ionizing radiation that require protection.

Principle of Attenuation

Attenuation is a fundamental concept in radiation shielding. It measures the reduction in intensity, or strength, of ionizing radiation as it passes through a shielding material. A key parameter that quantifies attenuation is the linear attenuation coefficient, which represents the rate at which the radiation is attenuated as it travels through the material. The higher the linear attenuation coefficient, the more effective the shielding material is in reducing radiation exposure.

Types of Ionizing Radiation and Shielding Materials

Different types of ionizing radiation interact with shielding materials in unique ways. Gamma rays, x-rays, and neutrons are three common forms of ionizing radiation that require effective shielding. Lead is a commonly used material due to its high density and effectiveness in blocking x-ray and gamma radiation. It can be used in various forms, including lead sheets, plates, bricks, and glass.

Neutrons, on the other hand, require different shielding materials. Concrete, plastics, and hydrocarbons are commonly used for neutron radiation shielding. Each material has specific properties that interact with neutrons and effectively reduce their penetration.

Example of Radiation Shielding Material – Lead

Lead is widely recognized for its excellent radiation shielding properties. Its high atomic number (82) and density make it an effective barrier against x-ray and gamma radiation. The table below illustrates the linear attenuation coefficients for different thicknesses of lead, showcasing its ability to attenuate radiation effectively:

| Lead Thickness (mm) | Linear Attenuation Coefficient (cm-1) |

|---|---|

| 2 | 0.21 |

| 4 | 0.10 |

| 6 | 0.07 |

The Importance of Effective Radiation Protection

Understanding the shielding properties and requirements of different materials is essential in designing effective radiation protection measures. By utilizing appropriate shielding materials, such as lead, individuals can minimize their exposure to ionizing radiation and mitigate potential health risks. Effective radiation protection helps create a safer environment, especially in industries where workers are regularly exposed to radioactive materials.

Shielding effectiveness, measured by the reduction in radiation intensity, ensures that the chosen materials are effective in blocking ionizing radiation. When designing radiation shielding solutions, it is crucial to consider factors such as the type of radiation, shielding material properties, and the thickness of the shielding required.

Conclusion

Building materials for EMF shielding, radiation shielding materials, and EMI shielding materials play a crucial role in creating a safe and protected environment. Understanding the options available, considering factors such as shielding effectiveness, galvanic compatibility, and design considerations, is vital for effective protection against electromagnetic fields and ionizing radiation. The selection of appropriate materials and the collaboration with experts in the field can ensure the optimal design and implementation of shielding measures. By prioritizing reducing exposure from internal sources, addressing external sources, and implementing proper shielding techniques, individuals can create a safer environment and minimize the potential health risks associated with EMF and radiation exposure.

Selecting the Right EMI Shielding Materials for Gaskets

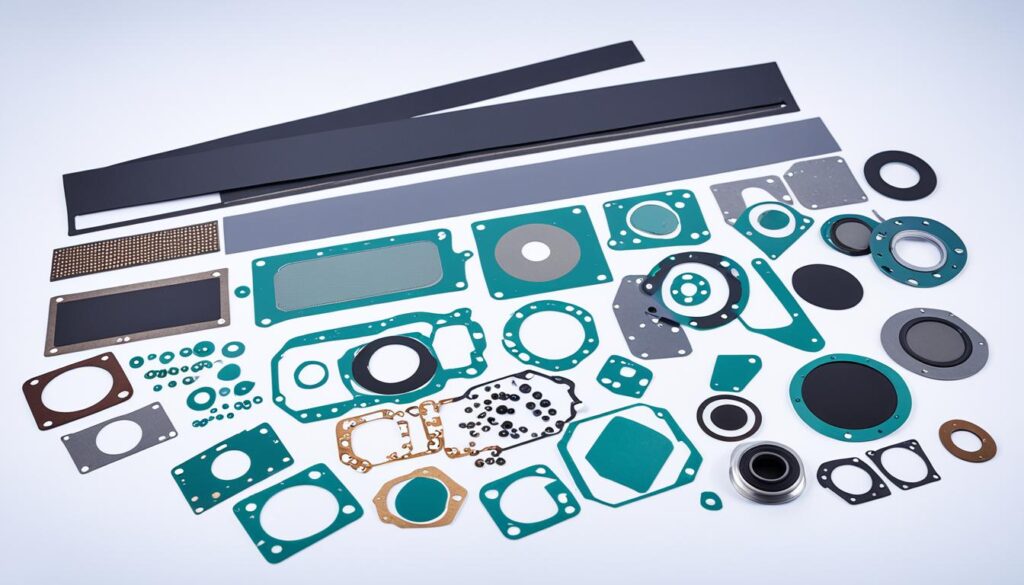

When it comes to choosing EMI shielding materials for gaskets, several factors need to be taken into consideration. The right selection can determine the effectiveness of shielding against electromagnetic interference (EMI) and ensure optimal performance. Here are the key factors to consider:

- Filler Type: The type of filler used in the shielding material plays a significant role in determining its cost and performance. Some common filler types include silver, silver aluminum, silver nickel, silver copper, and nickel graphite. Each filler type offers different levels of conductivity and shielding effectiveness, so it’s important to align the material choice with the specific requirements of the application.

- Galvanic Compatibility: Galvanic compatibility refers to the material’s ability to resist corrosion when in contact with other metals. It is essential to choose a shielding material that is compatible with the metals it will come into contact with. This ensures long-term reliability and prevents potential galvanic corrosion issues.

- Shielding Effectiveness Requirements: Consider the required level of shielding effectiveness for the specific application. In military and high-security applications, stringent standards need to be met. Depending on the requirements, different materials may be suitable to achieve the desired level of shielding effectiveness.

- EMI Shielding Material Categories: EMI shielding materials for gaskets can be categorized into three main types: form-in-place (FIP) materials, rubber-based materials, and foam and fabric over foam solutions. The selection of the material depends on factors such as gasket size, shape, complexity, compression forces, and environmental sealing requirements. Each material type offers unique advantages and disadvantages, so it’s important to assess the specific application needs.

Working with experts in the field can help narrow down the options and choose the most suitable EMI shielding material for gaskets. Their knowledge and experience can ensure the material selected aligns with the specific requirements of the application, providing optimal EMI protection.

EMI Shielding Materials for Gaskets Comparison

| Material Type | Advantages | Disadvantages |

|---|---|---|

| Form-in-Place (FIP) Materials |

|

|

| Rubber-Based Materials |

|

|

| Foam and Fabric Over Foam Solutions |

|

|

Understanding the Design Considerations for EMI Shielding Gaskets

In the design phase of EMI shielding gaskets, several important considerations need to be addressed. These considerations play a crucial role in ensuring the optimal selection and design of the gasket material for effective electromagnetic interference (EMI) shielding.

Filler Types

Choosing the right filler type is crucial in determining the cost and compatibility of the gasket material with other components. The filler types commonly used for EMI gasket materials include:

- Silver

- Silver aluminum

- Silver nickel

- Silver copper

- Nickel graphite

Each filler type offers different advantages and considerations, such as conductivity, thermal properties, and cost. It is important to assess the specific requirements of the application to select the most suitable filler type.

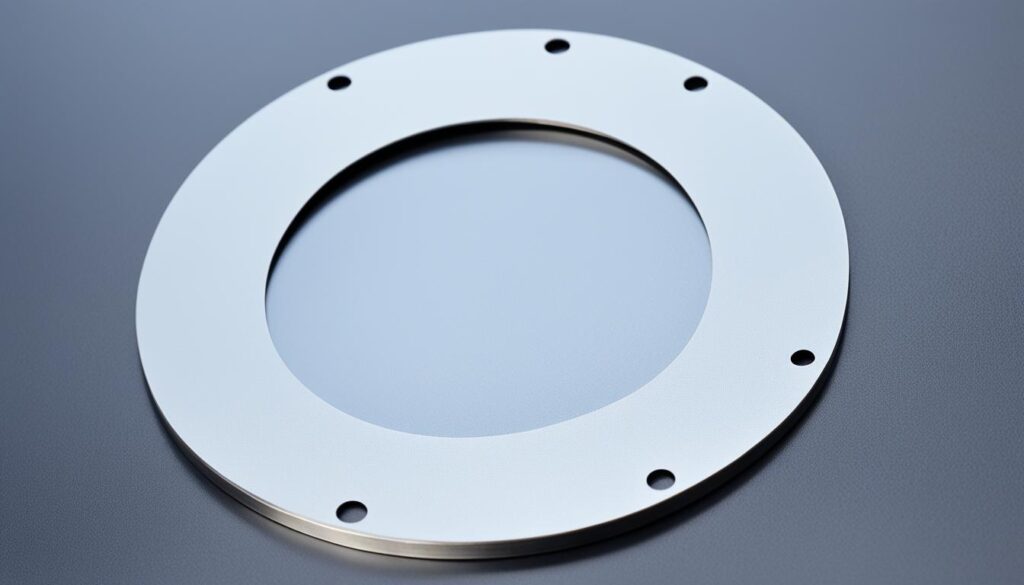

Galvanic Corrosion

Galvanic corrosion occurs when there is an exchange of electrons between metals. To prevent galvanic corrosion, it is crucial to select filler materials that are compatible with the housing of the gasket. Consider the materials that will be in contact with the gasket and choose a filler type that will not cause corrosion when in contact with these metals. This ensures the longevity and reliability of the EMI shielding gasket.

Shielding Effectiveness Requirements

Understanding the shielding effectiveness requirements is important, especially in military applications and other industries where compliance with stringent standards is necessary. Different applications may have specific requirements for shielding performance, and it is essential to select a gasket material that meets these requirements. Consult industry standards and specifications to ensure the chosen material provides the desired level of shielding effectiveness.

FIP Dispensing, Solid Rubber-Based Materials, Foam-Based Materials

The design process for EMI shielding gaskets involves choosing the right material based on factors such as gasket size, shape, complexity, and compression forces. Several options are available, including:

- Form-in-place (FIP) dispensing materials: These materials offer flexibility in achieving intricate gasket designs. FIP dispensing allows for precise placement of the gasket material and is suitable for complex shapes.

- Solid rubber-based materials: Solid rubber-based materials are known for their durability and physical strength. They can withstand compression forces and environmental factors, making them suitable for demanding applications.

- Foam-based materials: Foam-based materials offer excellent sealing properties and are ideal for applications that require both shielding and environmental sealing. They can conform to irregular surfaces and provide effective EMI protection.

Environmental Sealing Considerations

Environmental sealing is an important consideration when designing EMI shielding gaskets. The gasket material should provide effective EMI shielding while also ensuring a reliable seal against environmental factors, such as moisture, dust, and contaminants. Carefully evaluate the sealing capabilities of the chosen material to meet the specific requirements of the application.

Collaborating with Experts

Collaborating with experts in EMI shielding gasket design can greatly facilitate the selection and design process. These experts have in-depth knowledge of different materials and their properties, allowing them to provide valuable insights and recommendations. Working with professionals ensures that the gasket material chosen is optimized for the specific application, providing reliable EMI shielding and meeting all necessary design considerations.

| Filler Type | Advantages | Considerations |

|---|---|---|

| Silver | High conductivity Thermal stability | Higher cost |

| Silver aluminum | Increased strength Good thermal conductivity | More expensive than pure silver |

| Silver nickel | Improved durability Moderate cost | May not be suitable for sensitive applications |

| Silver copper | Enhanced corrosion resistance Good electrical conductivity | Lower thermal conductivity than pure silver |

| Nickel graphite | Cost-effective option Good electrical shielding | Lower overall conductivity |

Conclusion

Building Materials for EMF Shielding, Radiation shielding, and EMI shielding are crucial components in creating a safe and protected environment. By understanding the available options and considering factors such as shielding effectiveness, galvanic compatibility, and design considerations, individuals can effectively protect themselves against the potential health risks associated with electromagnetic fields and ionizing radiation.

Choosing the appropriate materials for shielding and collaborating with experts in the field ensures the optimal design and implementation of shielding measures. Prioritizing the reduction of exposure from internal sources, addressing external sources, and implementing proper shielding techniques are key steps to creating a safer environment.

With Building Materials for EMF Shielding, Radiation shielding, and EMI shielding, individuals can minimize their exposure to harmful electromagnetic fields and ionizing radiation, thus reducing the potential risks to their health. By taking proactive steps to shield their living and working spaces, individuals can enjoy a safer and healthier environment.

Source Links

- https://www.shieldyourbody.com/whole-home-emf-shielding/

- https://www.radetco.com/your-complete-guide-materials-that-block-radiation/

- https://www.modusadvanced.com/resources/blog/emi-shielding-materials-guide

Subscribe to Our Newsletter